Equipment display

Production equipment - Jane

The company's equipment in tubing processing is readily available, with a total of more than 200 sets of new special processing equipment. Most of the new special processing equipment are pioneers in the industry. Among them, key equipment such as CNC pipe bending machines, pipe end forming machines, and high-pressure oil pipe inner wall strengthening equipment initially All imported from abroad, the first to reach the same level in the world; the basic equipment of the company's industry includes ordinary lathes, CNC lathes, CNC surface grinders, drilling machines, drilling and milling machines, milling machines, planers, wire cutting machine tools, ordinary steel pipe blanking machines, automatic steel pipe blanking machines , flat head chamfering machine, automatic grinding machine, punching machine of various tonnage, bellows forming machine, rotary groove machine, ultrasonic cleaning machine, sub-arc welding machine, laser spot welding machine, gas welding machine, mesh belt brazing furnace, pneumatic marking machine, laser marking machine, crimping machine, hydraulic cleaning machine, flow measuring instrument, air tightness detection device; the company has also independently developed a variety of special equipment in the industry, and some of the equipment has also applied for patent equipment, such as: sandblasting machine, Washing machine, airtight test equipment, flow test equipment, etc.

01 Key production equipment

Pipe bending machine

Quantity: 18

Diameter range:φ4~φ75

Minimum bending radius

capability:1.2*OD(external diameter)

Maximum bending radius of double-layer die:

2

Spatial intersection accuracy after bending:±0.25mm

Scope of application: automatic bending of high and low pressure metal oil pipes

Tube end forming machine

quantity:18

Diameter range:φ4~φ75

Tube end forming dimensional accuracy:±0.02

Scope of application: high and low pressure metal tubing end forming

Bender

quantity:3

Diameter rang:φ4~φ75

Drilling diameter:φ0.7~φ10

Radius of machining

area:1.5m

Suitable for product circumferential angle:360 degrees (requires special tooling)

Suitable for axial spacing: 0.5 drill diameter

Scope of application: processing of welding holes and nozzle holes

Tube end forming machine

quantity:1

Applicable product range: high-pressure oil pipes above China IV

maximum intensification pressure:550Mpa

Reinforcement time:6~8S

Improve overall

performance:20%~30%

Working principle: In the manufacturing process of high-pressure

fuel pipe, by applying ultra-high pressure on the inner wall of the fuel pipe, the inner

wall of the high-pressure fuel pipe is yielded, resulting in plastic deformation, and

then the pressure is relieved, thereby improving the overall performance of the product.

brazing furnace

| Model | Quantity | Maximum operating temperature | Mesh belt width(mm) | Protective gas | Workspace size | Suitable for welding product material types |

|---|---|---|---|---|---|---|

| RCWE12-13×180×8 | 1 | 1150 | 130 | Ammonia Decomposition - Nitrogen | 160* | All carbon steel parts |

| RCWE12-18×260×16 | 1台 | 1150 | 180 | Ammonia Decomposition - Nitrogen | 210* | Stainless Steel Products |

Dust-free cleaning, drying and packaging equipment

Quantity: 1 production line

Processing range of pipe fittings: high pressure oil pipe (all

specifications) low pressure oil pipe (≤φ38)

Cleaning pressure:

0.6~15Mpa

Cleaning time: Program control can be adjusted arbitrarily

drying temperature:≤150℃

Scope of application: cleaning, drying, rust prevention, packaging, etc. of high and low pressure oil pipes

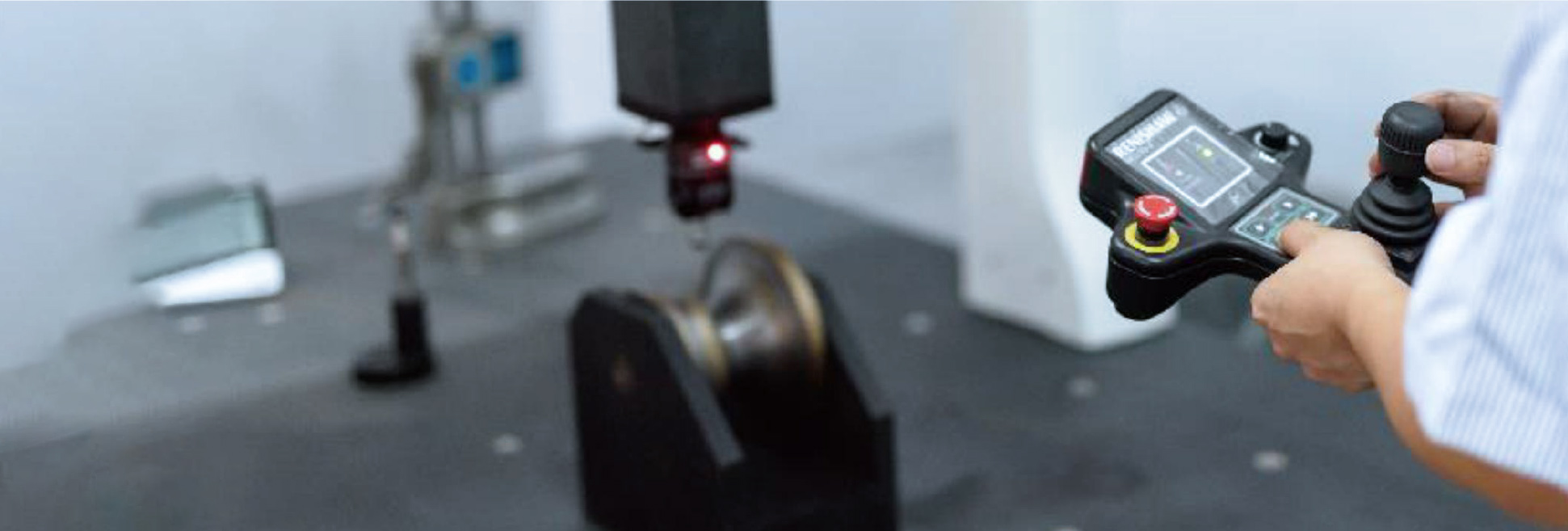

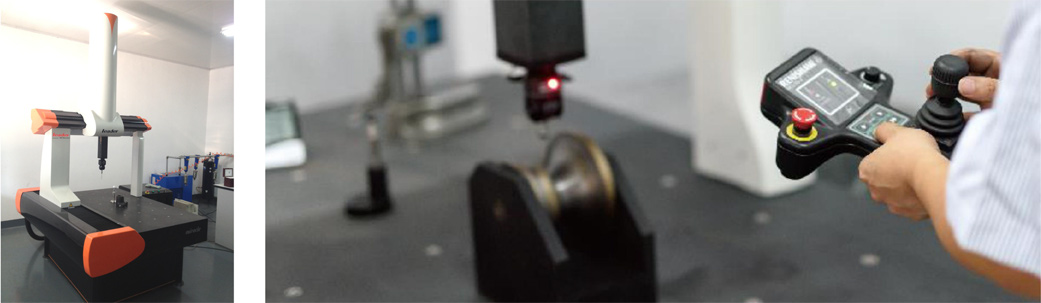

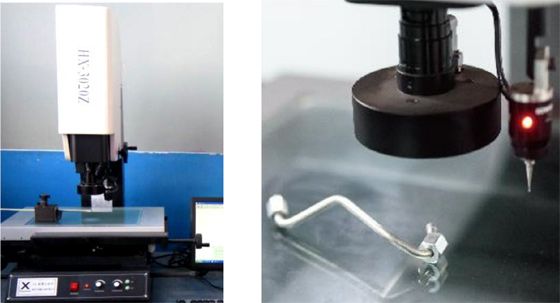

02 Main testing equipment

Three coordinates: 1

range of travel:800×1500×700

allowable workpiece range:900×1600×800

Accuracy Index:MPEP(μm:2.7)

MPEE(μm):2.7+3.3L/1000

Image measuring instrument:1

range of travel:300×200

Accuracy Index:X、Y、Z

Digital display resolution:0.5µm;

X, Y coordinate indication error:≤(3+L/75)μm